Mining Ore Lead Manganese Iron Slag Sliver Aluminum Zinc Cement Powder Grinding Wet Gold Copper Ball Mill

Overview Package size per unit product 600.00cm * 200.00cm * 220.00cm Gross weight per unit product 16000.000kg Product

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | YMQ1545 |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Motor Power | 15KW |

| Rotationl Speed | 20-22r/min |

| Application | Mine |

| Materials | Gold |

| Condition | New |

| Warranty | One Year |

| After-sales Service | Installation and Technical |

| Price | Negotiable |

| Machine Application | Stone Ore, Gold, Copper, and Other Ores |

| Machine Color | as Your Require |

| Pre-Service | Free |

| Installation | Under Our Engineer Guide |

| After-Service | for Whole Using Life |

| Capacity(T/H) | 0.3-155 |

| Certification | ISO9001:2008, CE |

| Mining Object | Ball Mill |

| Delivery Time | 15 Days |

| Customized | Yes |

| Transport Package | Standard Container |

| Specification | ISO, CE, SGS |

| Trademark | HC |

| Origin | Gongyi City, Henan Province, China |

| HS Code | 8474100000 |

| Production Capacity | 150 Set/Year |

Packaging & Delivery

Package size per unit product 600.00cm * 200.00cm * 220.00cm Gross weight per unit product 16000.000kgProduct Description

China professional Mining Ore Lead Manganese Iron Slag Sliver Aluminum zinc cement Powder Grinding Wet Gold Copper Ball Mill

*General introduction:Ball mill is a kind of grinding machine used to grind the crushed materials into extremely fine power, this series ball mill is mainly applied for industrial and mining enterprise such as Mining Ore Gold Copper Lead Manganese Iron Slag Sliver Aluminum Limestone Gypsum Powder ,metallurgy, building materials, chemical and other grindable materials, it can be used for wet and dry milling, open circuit grinding, also for the circle grinding with power feeder. This machine has it's own advantage of rational design, strong adaptability to raw materials, running fast, high crushing ratio, large capacity and easy to operate.*Hengchang Ball mill Advantage:

Our factory's high efficient ball mill adopts automatic self-aligning double row centripetal spherical roller bearing, and has the advantages of smaller resistance and remarkable energy-saving effect. This machine has its own advantage of rotation design, strong adaptability to raw materials, running fast, high crushing ratio, large capacity and easy to operate.

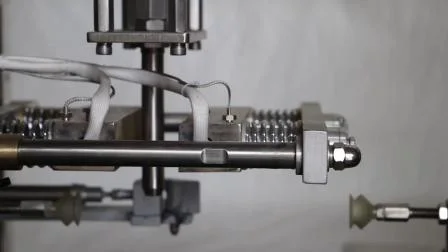

*Ball mill desighBall Mill consists of feed&discharge parts, rotary shell, transmission part and other major components. Hollow shaft is with steel parts, lining is removable. Rotary gear adopts casting hobbing, and the tube body is with resisting liner.The ball mill produced by our plant includes wet grid type, dry grid type and overflow type.

* Characteristics1. Large ring gear, large side cover and large bearing. The gear hub is large, which can prolong its service life, and adopts high-frequency quenching heat treatment process on the modulated surface; The sprocket adopts high-frequency quenching heat treatment process on the modulated surface.2. Energy saving: Ball bearings are used instead of slide bearings, which greatly reduces the frictional force, makes starting easier, and saves 10-15% of energy consumption compared with the old ball mill .3. Large processing capacity: Due to the use of the discharge disc and grate plate of the standard mill, the processing capacity is increased by more than 20% compared with the energy-saving conical ball mill.4. The mud surface of the discharge port is low, and the mud can pass quickly, which can reduce the excessive grinding of the ore.5. There are many loaded balls, large and small balls can be loaded, and small balls will not be discharged, and good working conditions can also be formed.6. The equipment is equipped with Support frame , more easier for clients installation in plant site. 7. The electronic control system has taken protective measures against motor overcurrent, power failure and three power supply imbalances, so as to realize the "worry-free" operation of the ball mill. Detailed PhotosProduct Parameters

Technical Data

Model | Rotate Speed (r/min) | Max. ball No (t) | Feed size(m) | Output size(mm) | Capacity(t/h) | Power (kw) | Weight (t) |

YMQ750×1800 | 39 | 1.0 | 0-15 | 0.075-0.3 | 0.3-0.8 | 11 | 3.5 |

YMQ900×2100 | 37.8 | 1.5 | 0-15 | 0.075-0.3 | 0.8-2.1 | 15 | 5.2 |

YMQ1200×2800 | 37 | 5.2 | 0-20 | 0.075-0.3 | 1.2-6.2 | 30 | 10 |

YMQ1500×3500 | 29.7 | 8.0 | 0-25 | 0.075-0.3 | 2.8-9 | 75 | 17 |

YMQ1500×4500 | 29.7 | 9.5 | 0-25 | 0.075-0.3 | 2.8-10 | 90 | 20 |

YMQ1830×3600 | 25 | 11.5 | 0-25 | 0.075-0.3 | 5.2-25 | 130 | 28 |

YMQ1830×4500 | 25 | 16.5 | 0-25 | 0.075-0.3 | 5.2-30 | 155 | 32 |

YMQ2100×3600 | 24.6 | 17.4 | 0-25 | 0.075-0.3 | 6.5-40 | 180 | 41 |

YMQ2100×4500 | 24.6 | 22.5 | 0-25 | 0.075-0.3 | 6.5-42 | 210 | 46 |

YMQ2400×3600 | 22.4 | 23 | 0-25 | 0.075-0.3 | 7.2-92 | 210 | 65 |

YMQ2400×4500 | 22.4 | 28.5 | 0-25 | 0.075-0.3 | 7.2-95 | 245 | 72 |

YMQ2700×3600 | 20.7 | 40 | 0-25 | 0.075-0.3 | 12-145 | 320 | 80 |

YMQ2700×4500 | 20.7 | 50 | 0-25 | 0.075-0.3 | 12-155 | 380 | 90 |

* Delivery of our ball mill

Installation Instructions* Customer Plant site of ball mill machine