Three Roll Rubber Mixing Mill

1- Name: Rubber mixing mill, Open mixing mill, Two roll mill, Open rubber mixing mill, rubber mixer. 2- USE: This machin

Send your inquiryDESCRIPTION

Basic Info

| Weight | <50 Tons |

| Type of General Rubber Machinery | Material Processing Machine |

| Type of Tire Machinery | Rubber Regeneration Machinery |

| Certification | ISO, Ce |

| Power | 10~100kw |

| Using Life | ≥15 Years |

| Customized | Customized |

| Roll | Cast Iron Alloy, Very High Hardness |

| Transport Package | Wooden Case |

| Specification | ISO9001, CE |

| Trademark | Guangyue |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 60 Sets/Month |

Product Description

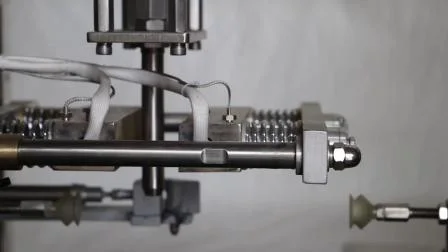

1- Name:

Rubber mixing mill, Open mixing mill, Two roll mill, Open rubber mixing mill, rubber mixer.

2- USE:

This machine is mainly used in Rubber & Plastic Product factory for Natural Rubber Mixing(plasticating), Raw Rubber and Compound mixing, rubber warm-up mixing and pressing sheet.

3- Main features:

A. The roll adopts the vanadium titanium metal alloy chilled cast iron and its surface is hard and wear-proof. The internal cavity is processed to make temperature well proportioned on the roll surface.

B. The rubber mixing mill is equipped with an overload protection device to prevent the main components from being damaged.

C. The rubber mixing mill is also equipped with an emergency brake device. When an emergent arises, just draw the safety pull rod, and the machine will stop immediately. It is safe and reliable.

D. The transmission system adopts a hardened tooth-surface reducer, which has a compact structure with higher transmission efficiency, lower noise and longer service life.

E. The base frame is a whole framework, which is convenient for installation.

F. Stock bender for direct rubber sheet and knife to cut as your need to assemble.

G. Auto-lubrication system for grease or oil and match bearing bush.

4- MODALITY:

A. Two roll rubber mixing mill: Common Gear Type (Nylon shoe, Copper shoe and Bearing).

B. Two roll rubber mixing mill: Reducer use Hard Tooth Face Type.

C. Two roll rubber mixing mill: B type. (The motor is under the roller).

D. Two roll rubber mixing mill: H type.

5- Parameters:

Type | XK-150 | XK-250 | XK-300 | XK-360 | X(S)K-400 | X(S)K-450 | X(S)K-560 | |

| Working diameter of rolls (mm) | Ø150 | Ø250 | Ø300 | Ø360 | Ø400 | Ø450 | Ø560 | |

| Working length of rolls (mm) | 320 | 620 | 750 | 900 | 1000 | 1200 | 1530 | |

| Working linear speed of front roll(m/min) | 8 | 15.1 | 15.1 | 16.25 | 18.65 | 24.5 | 27.7 | |

| Max gap (mm) | 10 | 10 | 10 | 10 | 15 | 15 | 15 | |

| Capacity per.batch(kg) | 1-2 | 10-15 | 15-20 | 20-25 | 18-35 | 25-50 | 50-65 | |

| Driving motor power(kw) | 7.5 | 18.5 | 22 | 30 | 37 | 55 | 95 | |

| Overall dimension (mm) | L | 1080 | 3400 | 3580 | 3940 | 4250 | 5200 | 6120 |

| W | 796 | 1350 | 1550 | 1780 | 1850 | 2380 | 2280 | |

| H | 1415 | 1500 | 1695 | 1740 | 1870 | 1770 | 2000 | |

| Weight (kg) | 1100 | 3500 | 5205 | 5670 | 7600 | 13000 | 22000 | |

| Notes | Bearing | Nylon bush grease LUB Copper sleeve oil LUB | Nylon bush grease LUB | |||||

Qingdao Guangyue Rubber Machinery Manufacturing

Add: Huangshan Economic Zone,Jiaonan, Qingdao City, China

0086-18661705828

Website: qdguangyue57.en.made-in-china.com

----------------------------------------------------

Related Products