Horizontal Screw Mixer for Powder and Fluid

Description of the horizontal screw mixer It consists of U-shape holder,belt stirring blade and the drive transmission p

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | JYHSM |

| Mixer Type | Powder Mixer |

| Working | Shear Mixer |

| Stirring Type | Spiral |

| Application | Liquid with Suspended Solids, Powder, Viscous Fluid, Granules |

| Certification | ISO |

| Application Area | Agricultural Chemicals |

| Layout Type | Horizontal |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Drying, Coating |

| Operating type | Continuous Operating |

| Condition | New |

| Transport Package | in Wooden Case |

| Specification | Customized |

| Trademark | JUNYI |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 50 Sets/Year |

Product Description

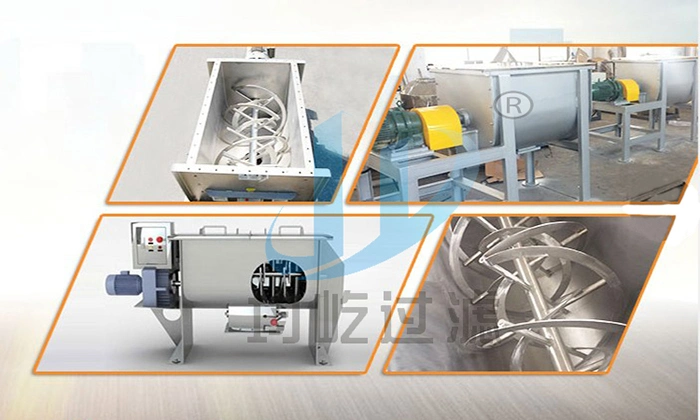

Description of the horizontal screw mixer

It consists of U-shape holder,belt stirring blade and the drive transmission part.The machine can be made of Carbon Steel and Stainless Steel. It can be also equipped with the jacket for the holder. It can heat, cool or vacuum in the jacket. The inside pressure of the jacket is less than 0.1 Mpa (The pressure can be customized). Two layers or three layers spiral blade makes the convection of the material to achieve the mixing effect rapidly. There is a discharging valve in the middle of the holder bottom.

Application:

It is used for the solid-solid (powder and powder) separation and the solid-pulp (powder and pulp liquid) separation such as in the industry of the pesticides,veterinary drugs,food,chemicals,biology,aquaculture,ceramics,refractory materials,plastics,compound fertilizers,etc.

Working principle

The horizontal screw mixer is driven by the inner and outer spiral rods installed on the mixing shaft to drive the material in the barrel so that the mixer can turn the material in the barrel to the maximum extent.The rods are designed to be opposite between the inner/outer spiral rods and left/right spiral rods.When the mixer is working,the inner spiral rod bring the material near the axis to rotate axially and the axis is pushed to the two sides from the inside.The outer spiral rod drives the material near the barrel wall to rotate axially and the axis is pushed to the inside from both sides.Then it will make the materials convection circulation and shearing blending in the barrel to make the materials are quickly and uniformly mixed in a short time.

About the reducer of the mixer

1. For the small mixer,the reducer with direct connection will be used.It has the advantage of simple structure,high reliability and convenient maintenance.

2. For the large mixer,it will be driven by the reducer with belt pulley.It has the advantage of protecting the transmission components during overload.

Customized parts for your choice:

1.Material:Carbon steel/304SS/316LSS/321SS/Manganese steel

2.Surface treatment:Sand blasting/polishing/anti-corrosion painting

3.Motor:Common motor/Anti-explosion motor/frequency conversion motor/high efficiency an energy-save motor/high protection level motor/motor with differential voltage

4.Reducer:R/K/F series gear reducer,cycloidal pin wheel reducer,general gear reducer,planetary gear reducer

5.Method of connection:Direct connection,wheel pulley connection,hydraulic coupling connection

6.More choice for the method of opening

7.According to the usage of the opening,we can open the mirror hole,cleaning door,feeding mouth,vent,dust revoming outlet.

8.Method of opening:Flange standard opening or quick open opening with cover

Different models of the Horizontal Screw Mixer

Pre-sale and after-sale service

Pre-sale service:1.Your inquiry will be replied within 6 hours.2.Help you to select suitable model3.Design totally according to your requirementsAfter-sale service:1.Provide 12 months warranty period and you will have our technology support forever2.Engineering available to offer the service to your machinery overseas

Frequently asked questions 1

Q:Please tell us the following information so that we can make you the offer Raw material: _____ Capacity:_____ Voltage: _____2

Q: Can you provide us the detailed drawing?Yes, we can provide you the drawing after have made the prepayment.3

Q: Are you a manufacturer or a trader?We're a professional and experienced manufacturer located in Zhengzhou.4

Q: Can you accept OEM?Yes, we can produce the machinery totally according to your design standard.5Q: How about the delivery time?Normally 10-20 working days after prepayment, and we promise we will make the delivery as soon as we can.

Contact us