5L-8000L Oil/Steam/Electric Heating Putty Plasticine Clay Dough Psa Hot Melt Adhesive Screw Extruder Hydraulic Tilting Double Z Arm Sigma Blades Kneader Mixer F

Overview Product Description 1. Uses:Sigma Mixer is widely applied to produce high-viscosity sealant, silicone rubber, n

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | NH-3000L |

| After-sales Service | Online Technical Guidance |

| Warranty | 1 Year |

| Mixer Type | Agitator |

| Working | Shear Mixer |

| Stirring Type | Forced |

| Application | Liquid with Suspended Solids, Viscous Fluid |

| Certification | CE |

| Application Area | Chemical |

| Layout Type | Horizontal |

| Mixing Drum Shape | Drum |

| Operating type | Continuous Operating |

| Condition | New |

| Type | Mixer |

| Usage | Industrial |

| Product Type | High Viscosity Materials |

| Volume | 5L-8000L |

| Plate Materials | Contacting Parts SS304/321/316L |

| Heating System | Hot Oil/Steam/Electricity Heating |

| Cooling System | Jacket/Wall Plate/Sigma Blades Cooling |

| Vacuum System | Water Ring Vacuum Pump |

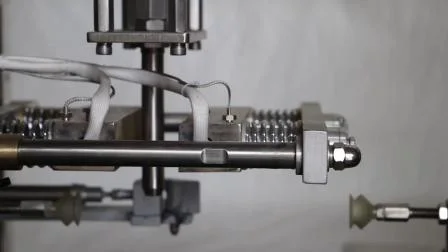

| Discharging | Hydraulic Tilting/Ball Valve/Screw Extruder |

| Cutter | 4 Blade Knives |

| Transport Package | Standard Wooden Case |

| Specification | CE |

| Trademark | Longteng |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 30PCS/Year |

Product Description

1. Uses:Sigma Mixer is widely applied to produce high-viscosity sealant, silicone rubber, neutral and acidic glass cement, chewing gum, bubble gum, paper pulp, and cellulose, and is also used in batteries, ink, pigments, dyes, pharmaceuticals, resins, plastics, rubber, cosmetics, and other industries.

2. Working Principle:Sigma Mixer is used to knead, mix, crush, disperse and re-polymerize high-viscosity paste or elastoplastic materials, which can not be processed by available powder mixers and liquid blenders.Sigma Mixer is the ideal equipment for all kinds of chemical products and has the merits of stirring evenly, kneading efficiently, and having no dead corners. The materials are scraped, stretched, folded, and squeezed among the blade, slot wall, and ridge-like protrusions.The materials cycle from one end of the impeller to the other. The two mixing paddles are tangent and spin at different speeds to complete the kneading process. 3. Category:There are four kinds of Sigma Mixer: Vacuum kneader, pressure kneader, atmospheric pressure kneader, and high-temperature kneader.It has three ways of discharging: Hydraulic tilting, ball valve, and screw extrusion.Characteristics

1. PLC control and record the temperature, time, viscosity, and other relevant data in real time during production.2. To ensure product quality, the parts of the cylinder and the blade that are in contact with the materials are made of stainless steel.3. The kneader can be used for the high-viscosity paste or plastic solid with poor mobility around 5000 Pa·s, and the jacket can be heated or cooled by heat transfer oil or water.4. According to the unique needs, the plant can be designed to operate in a vacuum.5. The speed difference between two shafts is 7.52r/min so the material is constantly changed, fastly mixed, and has a larger transfer area for unit volume.

The hydraulic tilting discharge type kneader is mainly composed of mixing and kneading part, machine base part, hydraulic system, transmission system, electric control system, heating system(optional), cooling system(optional), vacuum system(optional).Product Parameters

Notes:(1) Our company can design the equipment according to the user's specific requirements.(2) For the last update of the technology, we will change the technical data without notice, and the correct parameters are subject to the real product.(3) If you are unsure which type to choose, please call us, and our professional sales engineers will recommend one for you.FAQ

Q1. What are your terms of packing?

A: Generally, we pack our goods in plywood cases. If your goods have one container, the goods can be packed without plywood, just be wrapped with the film to load.Q2. What are your terms of payment?

A: T/T 40% as deposit, and 60% before delivery. We'll show you the photos of the products and packages before you pay the balance.Q3. What are your terms of delivery?

A: FOB, CFR, CIF, DDU.Q4. How about your delivery time?

A: Generally, it will take about 30 days after receiving your advance payment for the customized machine. The delivery time depends on the items and your order quantity.Q5. Can you produce it according to the drawing?

A: Yes, we can produce according to your technical drawings. If you don't have the drawing, just tell us your need and our engineer will make the drawing for your reference.Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before deliveryQ7. How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive prices to ensure our customers benefit;2. We respect every customer as our friend and sincerely do business and make friends with them, no matter where they come from.

Machining Strength

Product Catalog

Related Products

-

![Automatic PVC Powder Compounding and Conveying System Automatic Converying Weighing Dosing Mixing System]()

Automatic PVC Powder Compounding and Conveying System Automatic Converying Weighing Dosing Mixing System

-

![Small Wet Ore Grinding Ball Mill Gold Mining Machine Extraction Equipment]()

Small Wet Ore Grinding Ball Mill Gold Mining Machine Extraction Equipment

-

![Lta400-700 Multifunction Grout Cement Mixer and Agitator for Sale]()

Lta400-700 Multifunction Grout Cement Mixer and Agitator for Sale

-

![500-1000 PVC High Speed Mixer for Plastic Powder Granules Mixing]()

500-1000 PVC High Speed Mixer for Plastic Powder Granules Mixing