1L Atmosphere Protection Internal Mixer Special Equipment for Titanium Alloy for Laboratory

Overview 1L Atmosphere Protection Internal Mixer Special Equipment For Titanium Alloy for laboratory Product Parameters

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 1L |

| Specification | customized |

| Trademark | Customized |

| Origin | China |

| Production Capacity | 500PCS/Month |

Product Description

1L Atmosphere Protection Internal Mixer Special Equipment For Titanium Alloy for laboratoryProduct Parameters| Name | internal mixer |

| Capacity | 1L |

| Drive motor | 5.5KW |

| Material of mixing chamber and rotor | Alloy steel |

| Rotor speed ratio | 1:1.25 |

| Vacuum pump | 2.2KW |

| Frequency transformer | 0-50r/min |

| Number of temperature control zones | Zone 3 (Normal temperature -200 ˚ C) |

| Heating power | 5.5KW |

| Weight | 1000KG |

| Installation dimensions | L800 * W950 * H1750MM |

Application

The Webron 1L atmosphere protection experimental mixer is mainly used for mixing and dispersion experiments of titanium alloys, copper alloys, aluminum alloys, tungsten alloys, and other materials. A small volume of 1L ensures that the experiment is completed with the least amount of material, avoiding material waste. Adopting imported oxygen content detection instruments to ensure accurate numerical values; The entire machine adopts multiple sealing devices to ensure no air leakage and can complete the experiment with the minimum air consumption. Since its launch, the Wilburen 1L atmosphere protection experimental mixer has been widely recognized by scientific research institutions and colleges;

Feature

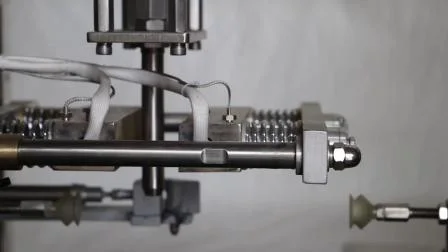

1: The mixing chamber and rotor are made of new alloy steel materials, which undergo special vacuum heat treatment, CNC machining, and surface mirror polishing treatment, ultimately achieving overall steel wear resistance and corrosion resistance (salt corrosion, acid corrosion, alkali corrosion, hydrogen sulfide corrosion, and other types of corrosion).

2: Servo coaxial separation technology, convenient for color cleaning and material replacement

Adopting advanced servo coaxial separation technology, with one end face of the rotor as the axis, it can be separated, breaking the bottleneck of traditional internal mixers. The open close internal mixer effectively controls unnecessary economic losses caused by material pollution. At the same time as the mixing room is opened and closed, the rotor is suspended in the middle, making it easy to clean and replace materials. The rotor can be disassembled, and the staff can clean any part, with a comprehensive design without dead corners.

3: The industry's first vacuum+atmosphere protected mode greatly reduces the inflation time

A: Vacuuming

Most of the air can be extracted in a short period of time, greatly reducing the inflation time.

B: Inert gas introduction (nitrogen or argon)

Users can set their own upper and lower oxygen content limits, and the equipment automatically starts and closes the inert gas switch, greatly saving gas consumption.

C: Oxygen content detection

A: Equipped with upper computer software, it can be connected to a computer for real-time monitoring, recording, saving, and exporting data

B: Original imported sensor, automatic temperature, zero and full drift compensation

C: High concentration gas shock protection and sensor fault self check function, safe and reliable

D: Detection accuracy: ≤ ± 3% (F.S)

E: Zero drift: ≤ ± 1% (F.S/year)

F: Linear error: ≤ ± 1%

4: PLC system automatic air replenishment

The equipment adopts a PLC control system, which can combine pre-set values and real-time detection, intelligently operate positive pressure to discharge the oxygen content during work, and automatically supply inert gas. Ensure that the entire working process can be carried out in accordance with the requirements of material mixing, thereby achieving better mixing results.

Company Profile

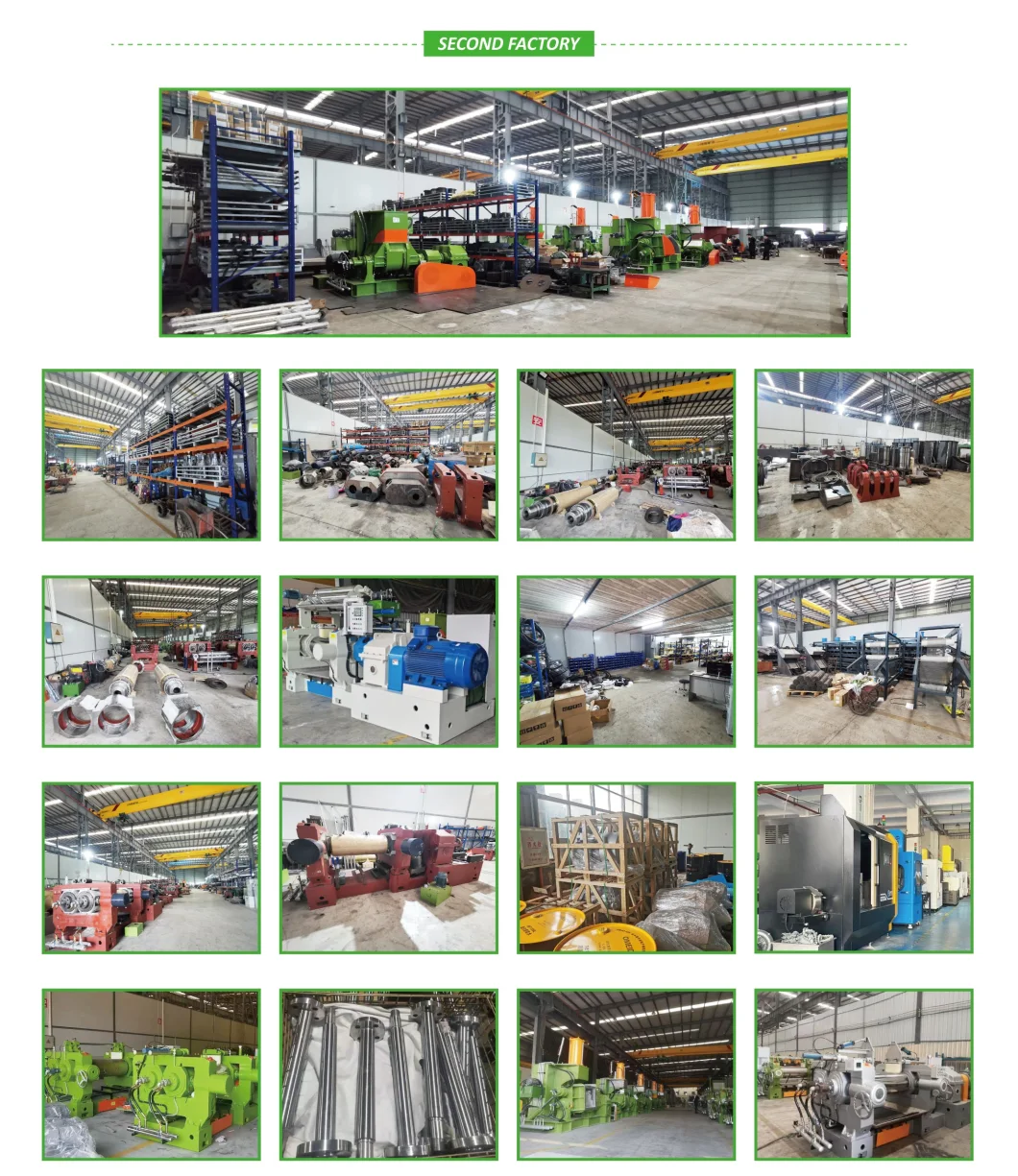

Xiamen Webron is a national high-tech enterprise, a star enterprise in Fujian Province, and a well-known innovative technology research and development enterprise. It was registered in the Cross-Strait Equity Trading Center in 2021, with the enterprise code of 867467; The headquarters is located in the Tsinghua Strait Research Institute. It is a 3A credit enterprise in China, a member unit of the Mechanical Mold Branch of the China Rubber Industry Association, a key recommended private enterprise in Fujian Province, and a member unit of the Fujian Plastic Industry Association; Signed contracts with 15 professors in the fields of polymer, metal, and ceramics, has industry-university-research cooperation with multiple universities, and has joint laboratories with universities; It is a metal ceramic rubber plastic machinery technology enterprise specializing in research and development, design, manufacturing and sales, and after-sales maintenance services. Company Vision: Let China's mixing technology synchronize with the world. Serving new material enterprises such as polymer materials, graphene materials, advanced ceramics, and powder metallurgy, our core products include torque rheometers, rubber internal mixers, metal internal mixers, ceramic internal mixers, internal mixing and granulation integrated machines, open mills, twin screw extruders, and plate vulcanizers.

The company has successively passed the certification of ISO 9001, intellectual property management system, and high-tech products. It has strong production capacity and advanced technological processing equipment, such as 10 five-axis CNC machining centers, 4 CNC lathes, 5 slow moving wire and other imported processing equipment. The company has independent laboratories, and various materials and experimental equipment are provided to customers for visiting/testing formulas/proofing. The professional R&D and design team can meet the special non-standard requirements of customers and customize the model, which has been recognized and praised by the majority of customers.

Since its establishment, Webron has worked hard, innovated, and made progress. The company promises to produce high-quality products for you with specialized technology, and to create higher value for you with high-tech achievements! Xiamen Webron Technology is willing to work with you to create a brilliant future!

Q1. How to choose the most suitable Mechanical Equipment ?

A1:Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

Q2. What's the delivery term?

A2:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q3. Do you accept customization service?

A3:Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don't hesitate to tell us your requirement, we will try our best to meet your needs.

Q4. Can we visit your factory before order?

A4:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q5. How about your warranty?

A5:1. Provide on-site installation guidance;

2. Responsible for on-site commissioning and trial run of the supplied equipment until it passes the acceptance;

3. Responsible for on-site operation and maintenance training for Party A's personnel;

4. The unit is warranted free of charge for one year under correct use, and the supply of spare parts is guaranteed for a long time;

5. Provide long-term free technical service consultation;

6. Within and outside the warranty period, the supplier shall provide clear solutions within 3 hours after receiving the buyer's equipment failure notification

Related Products

-

![Industrial Plastic Granules/Polymer Compounding Powder Mixer/Plastic Mixing Machine]()

Industrial Plastic Granules/Polymer Compounding Powder Mixer/Plastic Mixing Machine

-

![Food Grade Belt Type Microwave Fungus Drying Equipment Industrial Customization]()

Food Grade Belt Type Microwave Fungus Drying Equipment Industrial Customization

-

![Combined Industrial China Food Processing Wastewater Treatment Sludge Drying Equipment]()

Combined Industrial China Food Processing Wastewater Treatment Sludge Drying Equipment

-

![30tph Fine Sand Rod Mill River Pebble Sand Rod Mill]()

30tph Fine Sand Rod Mill River Pebble Sand Rod Mill